Section 2 Differences between conventional calculation (ABC analysis) and Tera calculation |

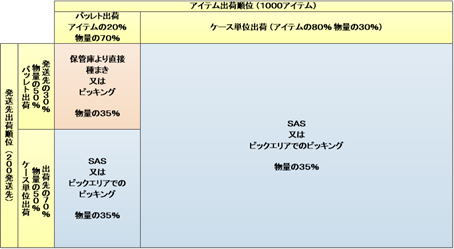

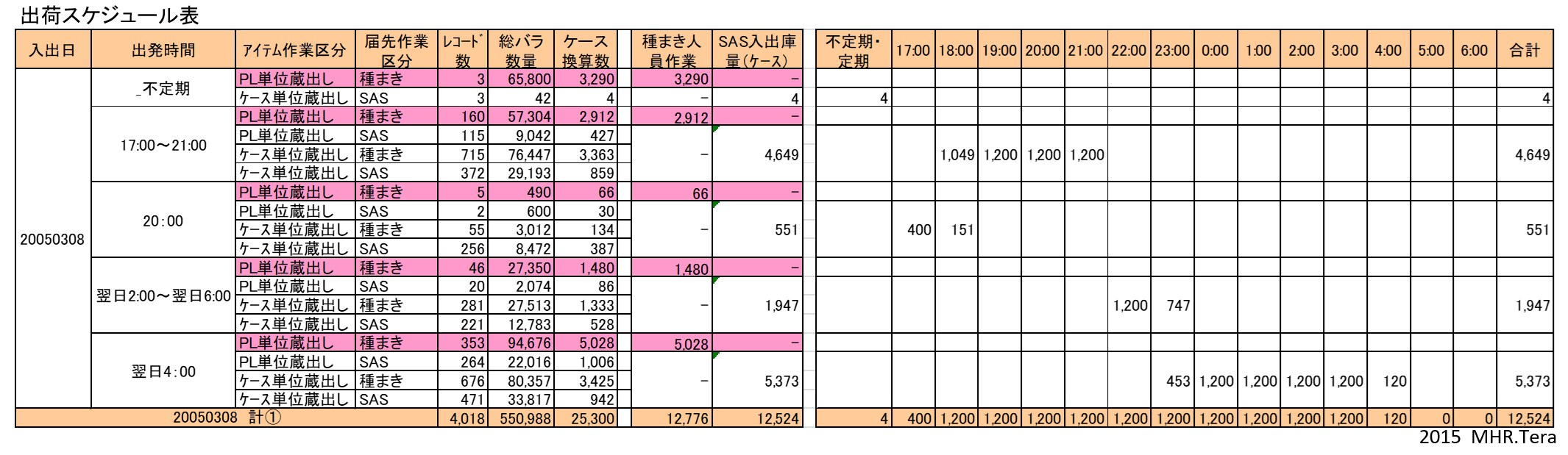

| In Tera calculations, calculations that use the ABC analysis method to tally data are called conventional calculations. ABC analysis divides ranks into thirds and performs tallying by rank and by shipping destination, while Tera calculations divide ranks into fifths and performs tallying by rank and by shipping destination. In conventional calculations, the totals for each item in the item tally and shipping destination tally are the same, but there is no correlation between the two tables. Therefore, conventional calculations cannot obtain information from these two tables about the shipping destination rank to which products with item rank A1 are allocated. When considering distribution center size and operation methods, or calculating logistics volume for each process, data that associates shipping destinations with items is required. Tera Calculation proposes a method of associating "time rank" with "shipping rank" and dividing and aggregating into 25 blocks (item rank 5 x shipping rank 5). In Tera Calculation, this aggregation table is called an EIQ matrix table. Tera Calculation is also designed to display the number of rows (number of issues), number of loose items, case conversion, PL conversion, volume conversion, and weight conversion, all separated by the same rank. By looking at this matrix table, for example, When an A1 rank item is stored on a flow shelf installed in the shipping work area, it is easy to calculate how many times it will be picked, what the total number of loose items is, what the volume is at that time, how many shipping containers are required, how many cases will be required to replenish the flow shelf from the storage area, and how many pallets will be required when it is transported from the storage area using a mixed PL. |