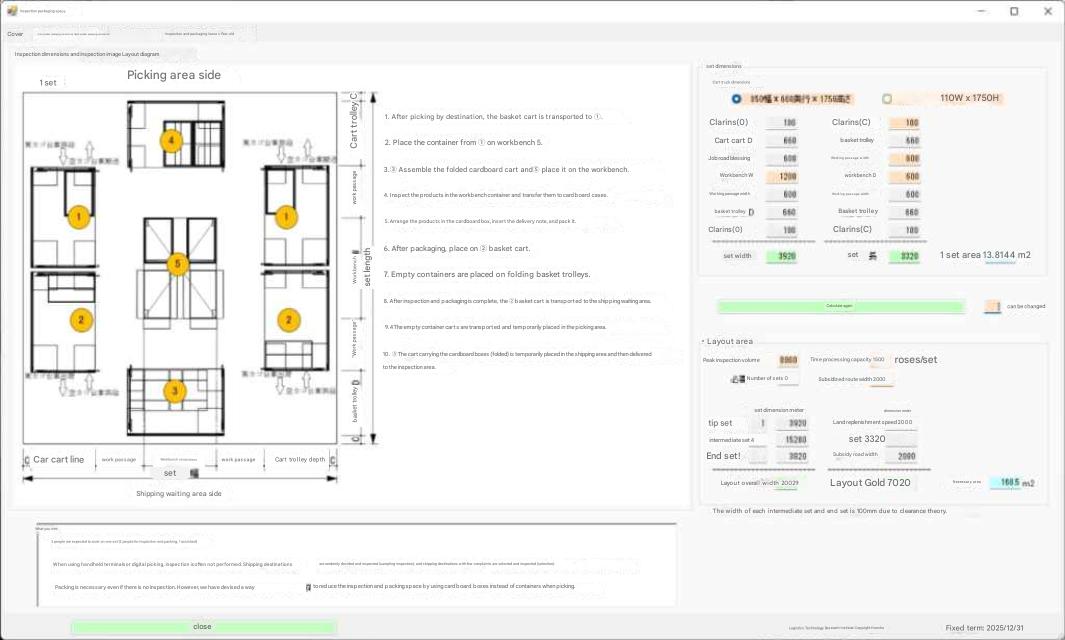

Inspection and Packing Calculation 1 assumes full inspection and packing work, while Inspection and Packing Calculation 2 assumes inspection-less work adopted in Tera Calculation (Distribution Center Size Calculation).

For inspection-less work, refer to "Chapter 4 Tera Calculation 2 Automatic Distribution Center Size Calculation, Item 7 Inspection and Packing Bulk Pic Flow Chart."

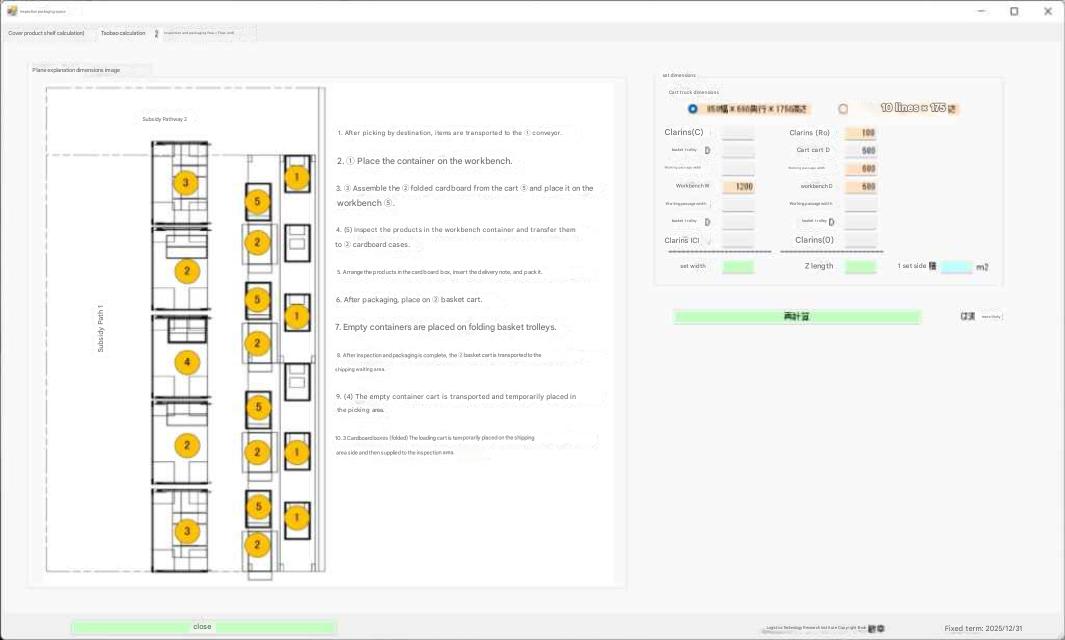

Section 1 Inspection and Packing Calculation 1 |

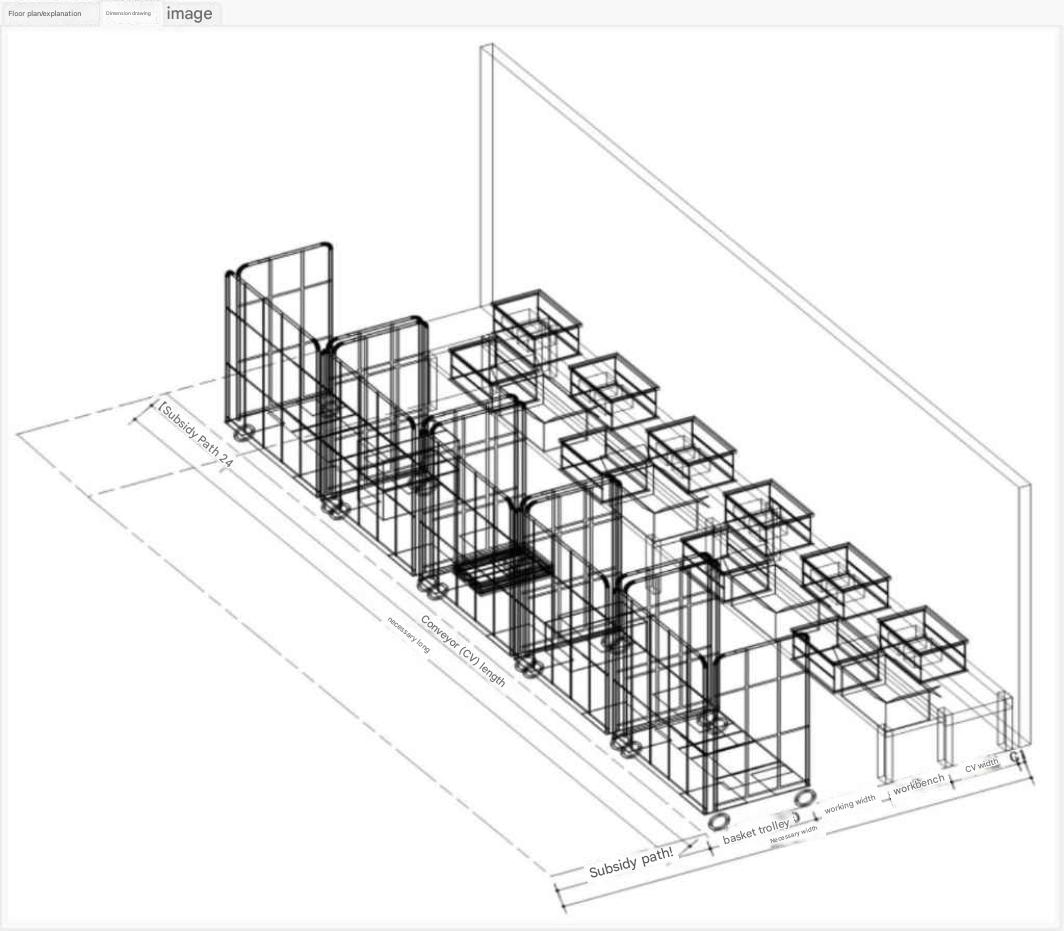

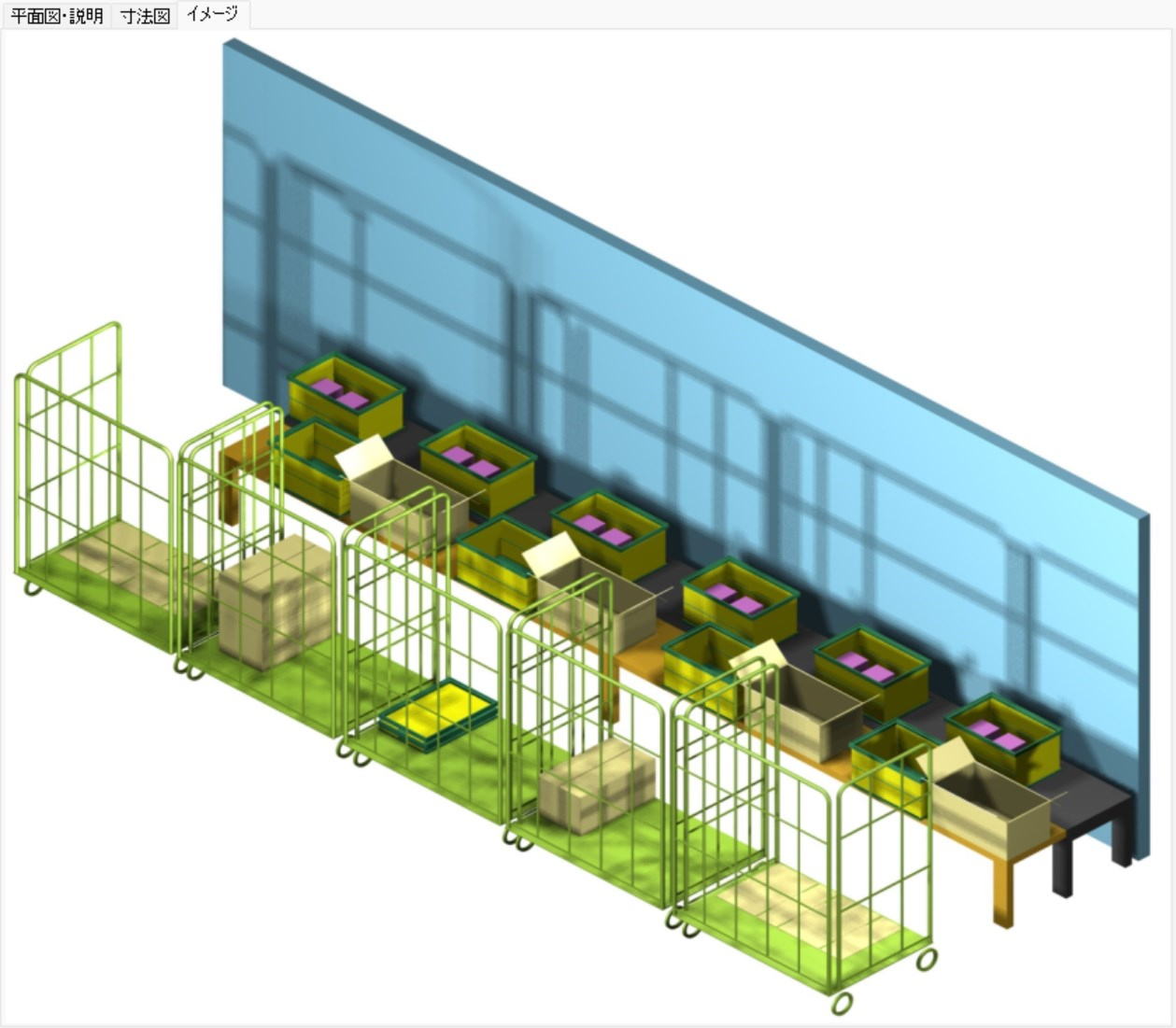

| Layout 3D image |

|

Assumes work by 4 inspection workers and 1 assistant. Work space will increase or decrease depending on the dimensions of the cart and operation method. Calculation example: Inspect 20,000 loose items per hour. Inspection takes 2 seconds per loose item. 4 people can inspect one set in 0.5 seconds per loose item. Hourly processing capacity per set = 3600/0.5 = 7,200 items. Number of sets required = 20,000/7,500 = 2.8 sets => Area required for 3 sets is 13m2 * 3 sets = 39m2. |