|

||

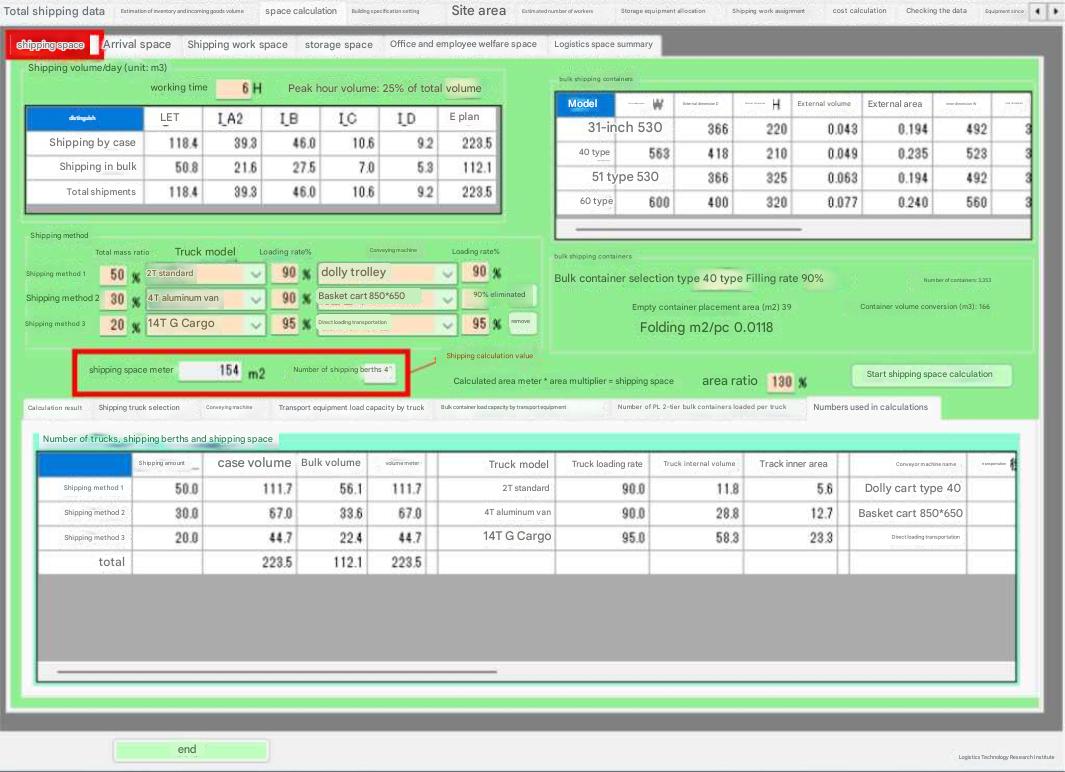

Item 1. Calculation of shipping space area and number of berths

| Shipment volume per hour, truck loading capacity |

Item 2. Peak shipping volumeTera Calculation 2 analyzes shipping data in advance and displays the ratio of high volume per hour = (high volume per hour / daily volume) * 100. Compare this volume ratio with each table displayed and enter the volume ratio.To increase equipment utilization rate, you want to keep the volume ratio below 25%. If it exceeds 30%, you can use 30% for Tera Calculation 2, which is a rough scale calculation, but when considering the details, you need to take measures such as bringing forward the volume ratio to reduce it, otherwise you will end up setting up equipment with excessive specifications. Section 3: Shipping Method and Total Volume RatioThree patterns of truck types can be calculated for shipment. The total volume ratio is the ratio allocated to each pattern when the daily shipment volume is 100%.Shipment truck types and loading rates: There are 11 types of truck types (2T standard, 2T long, 2T long wide, 4T wing truck, 4T aluminum truck, 4T aluminum van, 4T wing truck, 10T super, 14T G cargo, 20ft container, 40ft container). Considering the narrow unloading area at the destination and on-road unloading, a smaller vehicle type is selected compared to the receiving truck; containers or large vehicles over 10T are never selected. The loading rate of shipping containers and transport equipment is lower than the receiving loading rate. Shipping loading method and transport equipment: Transport equipment such as carts are often used to reduce unloading time. There are seven types of transport equipment to choose from (direct loading transport, pallet 1100*1100, basket cart 850*650, basket cart 1100*800, dolly cart, double-sided 6-wheel cart, double-sided cart). Basket carts are often used for cases, and dolly carts and double-sided carts are often used for bulk containers. Item 4. Bulk shipping containersDedicated deliveries, which deliver regularly to large destinations, allow for the return of transport equipment and containers. Meanwhile, for small-lot or individual destinations, shared delivery or courier services are used. Co-delivery and courier services, which involve joint delivery with other companies, are one-way, and dedicated deliveries do not allow the return of transport equipment or containers.In-house (dedicated) deliveries can use transport equipment and shipping containers, while shared and courier deliveries ship in cardboard packaging. The process flow is as follows: After inspection, the shipping container is used until both picking is complete. Based on the shipping category (shipping container/cardboard) in the shipping data, the shipping category (shipping container) is shipped as is, while the shipping category (cardboard) is repackaged and shipped. |

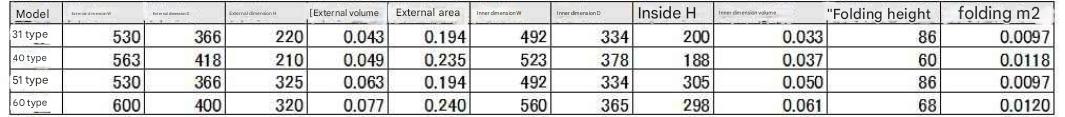

Shipping containers can be configured as four types: 30, 40, 51, and 60. The number before the type indicates the capacity in liters. Fill rate = product volume / container internal volume. The upper limit is 90%, with a lower limit of around 70% for larger products or when cushioning material is required. In addition, factors that reduce the fill rate include shipping containers with a small shipping volume that does not reach the shipping container's capacity, and fractional shipping containers even when multiple shipments are made. A fractional shipping container is a shipping container that contains 0.5 of a shipping container when three shipping containers are shipped and the product is 2.5 shipping containers. The same meaning applies to fractional pallets and fractional carts. Standard shipping containers are foldable, allowing for a smaller volume. The calculation of empty shipping container storage space assumes that the containers are folded five levels high and loaded onto a dolly when returned. The storage space for a 40-type empty shipping container is calculated to be 0.0118 m2 per container. A dolly is a cart designed specifically for containers. Item 5: Shipping Space Area RatioThe calculation of shipping space area does not take into account gaps between cargoes, work flow, or loading and unloading within the shipping space. The necessary area is calculated by multiplying it by a factor of 120% to 130%.Explanation of the table on the tab page: The Calculation Results tab page shows the calculation process and results of the shipping space in a table. Other tab pages include shipping truck specifications, transport equipment specifications, transport equipment load capacity by truck, bulk container load capacity by transport equipment, number of PL 2-tier bulk containers loaded by truck, and the values used in the calculation. The calculation results are displayed in a table. |