Item 2: Estimated Inventory Quantity |

|

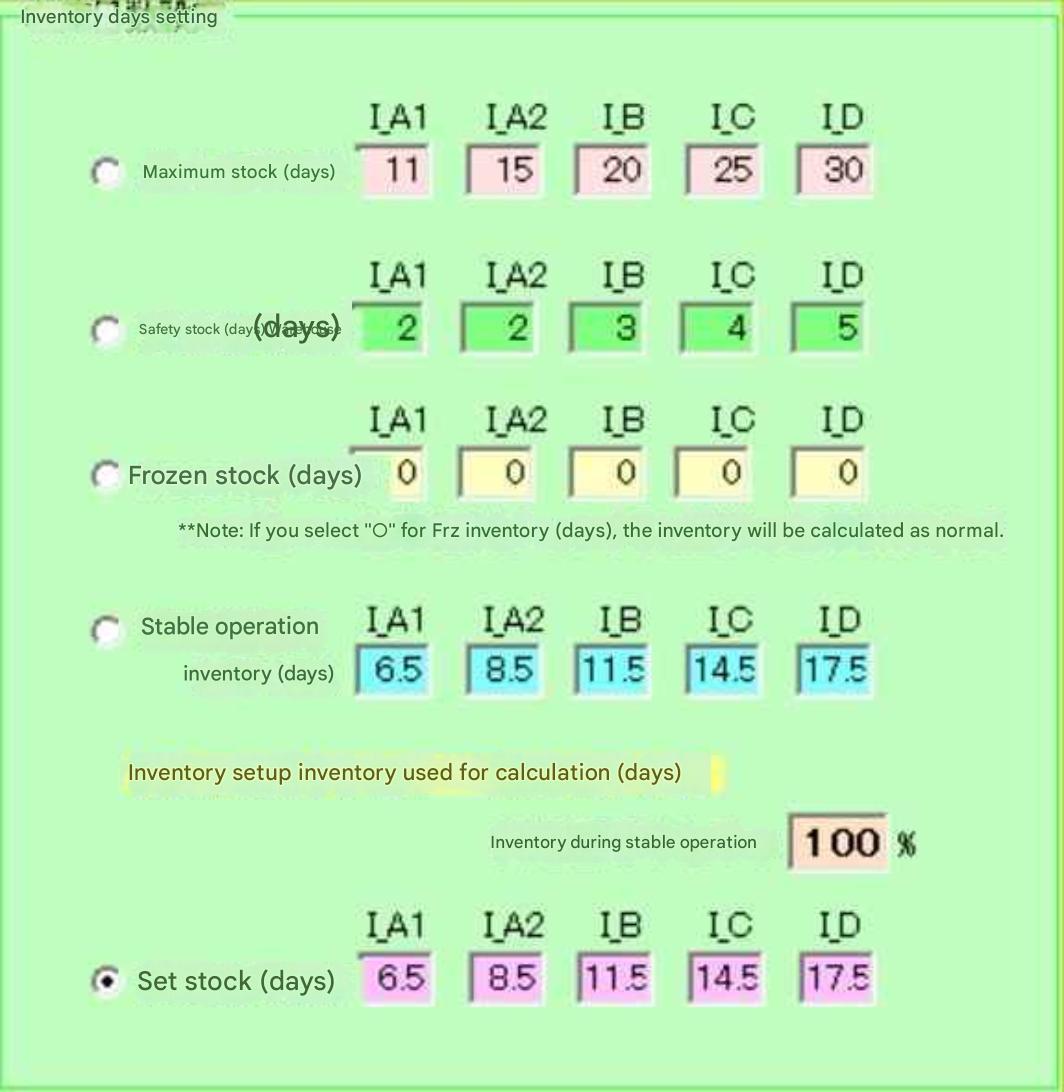

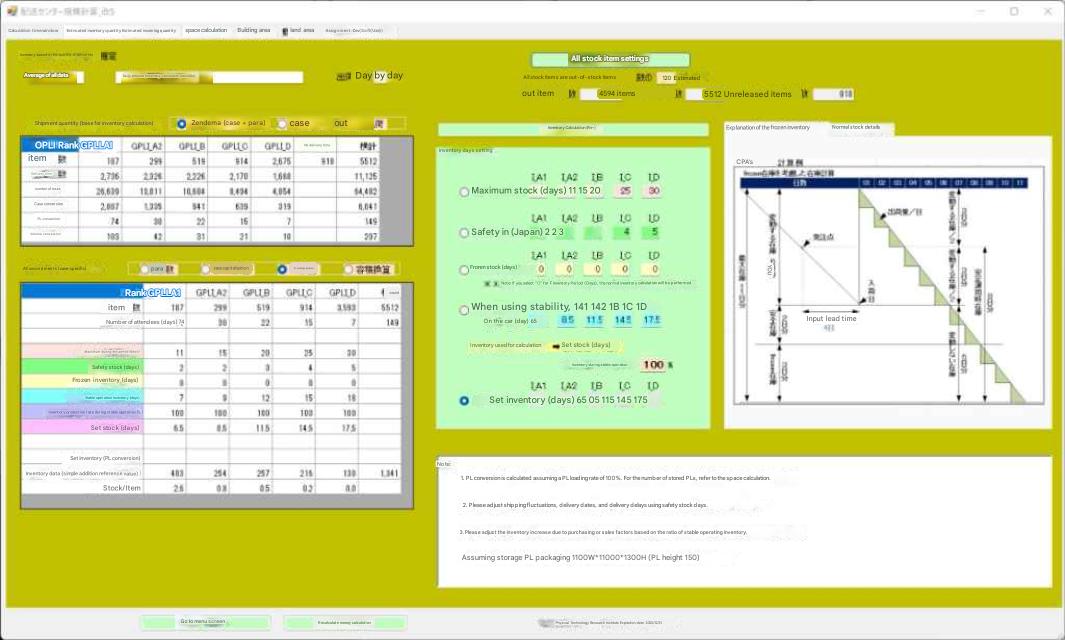

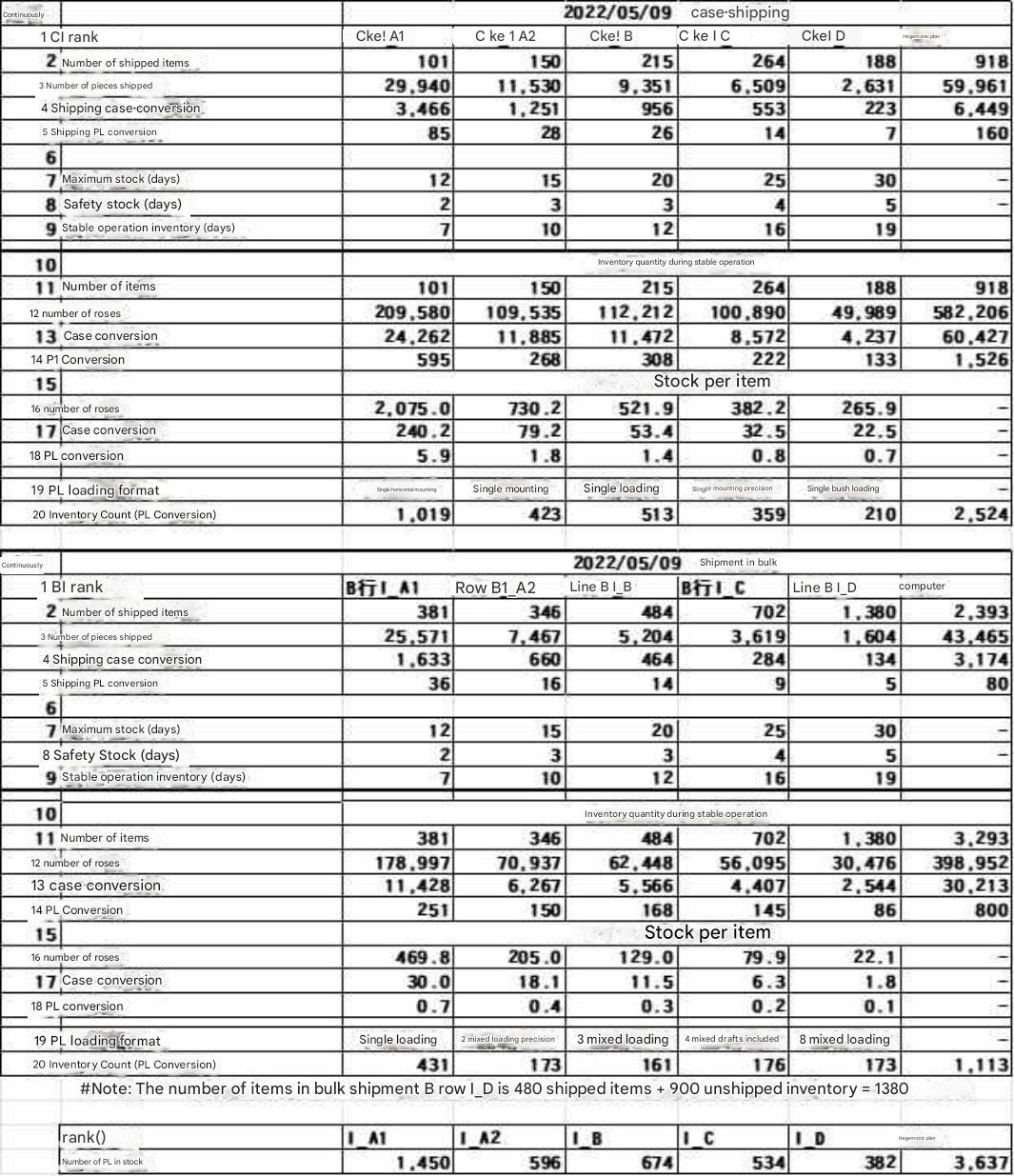

The method for calculating inventory quantity from shipping data was described in the previous section. As an example, we will explain the procedure for calculating inventory quantity ( PL equivalent) from shipping data 2022/05/09 . 1. Calculate the shipping quantity for 2022/05/09 by item rank (sequential numbers 1-5 ). 2. Specify the maximum inventory quantity (days) and safety stock (days) (sequential numbers 7-8 ) and calculate the stable operation inventory (days). The formula is stable operation inventory = (maximum inventory ( days ) - safety stock ( days ) ) / 2 + safety stock ( days ) (sequential number 9 ). 3. Calculate the stable operation inventory quantity. The formula is shipping volume * stable operation inventory (days). 4. Calculate stable operation inventory * shipping volume (sequential numbers 10-14 ). For serial numbers 16-18 , calculate stable operation inventory / number of items. 5. The key to this spreadsheet is calculating the pallet loading method. Single loads are 1 item loaded on a pallet, 2-item mixed loads are 2 items loaded on a pallet, and in mixed loads the first number indicates the number of items loaded on the pallet. The method for distinguishing single loads and mixed loads is that if the inventory per item ( PL conversion) is 0.5PL or more it is a single load, 0.5PL to 0.33 is a 2- item mixed load, 0.32 to 0.25 is a 3- item mixed load , 0.24-0.125 is a 4- item mixed load, and 0.125 or less is an 8- item mixed load. The PL conversion for mixed loads is calculated as the number of items / number of items loaded in the PL . |

Tera calculations add the number of unshipped items to the number of shipped items in row B, rank I_D for bulk shipments. Also, when calculating storage space, the amount is calculated as 1.1 times the amount calculated above ( Tera settings). Note: This calculation is a simple aggregation of the PL conversion of shipping data. The number of loads per PL must be taken into consideration.