The location where a distribution center will be built is called its location,

and various legal restrictions (location conditions) apply depending on

the location. Even the City Planning Act alone divides it into 13 uses, including residential,

commercial, and industrial. Other factors, such as the Building Act,

Fire Service Act, Radio Act, and coordination with neighboring residents ,

make site selection difficult enough that only experts can handle them.

Site area (or building area) is always required when selecting a site. Outsourcing

this process requires time and money, and additional internal burdens,

such as site surveys (to set prerequisites for area calculations).

Tera Calculation 2 is software that teaches users how to calculate the area

and size of logistics space from shipping data. To provide reference data

for site selection, we have added software to calculate site area (building

area). Please note that these calculations are for reference only

and not fixed values. The final area should be determined by adjusting

the calculation based on other conditions and other documents.

Buildings can only be constructed using blueprints drawn by qualified

architects ( 1st and 2nd class architects); unqualified individuals cannot determine the building

specifications. However, it is possible and necessary to have an idea of the area and

scale of the distribution center. The building drawings shown in Tera

Calculation 2 are only an image, not a blueprint. The building dimensions

shown in Tera Calculation 2 are tentative dimensions and are used only

to calculate the approximate area.

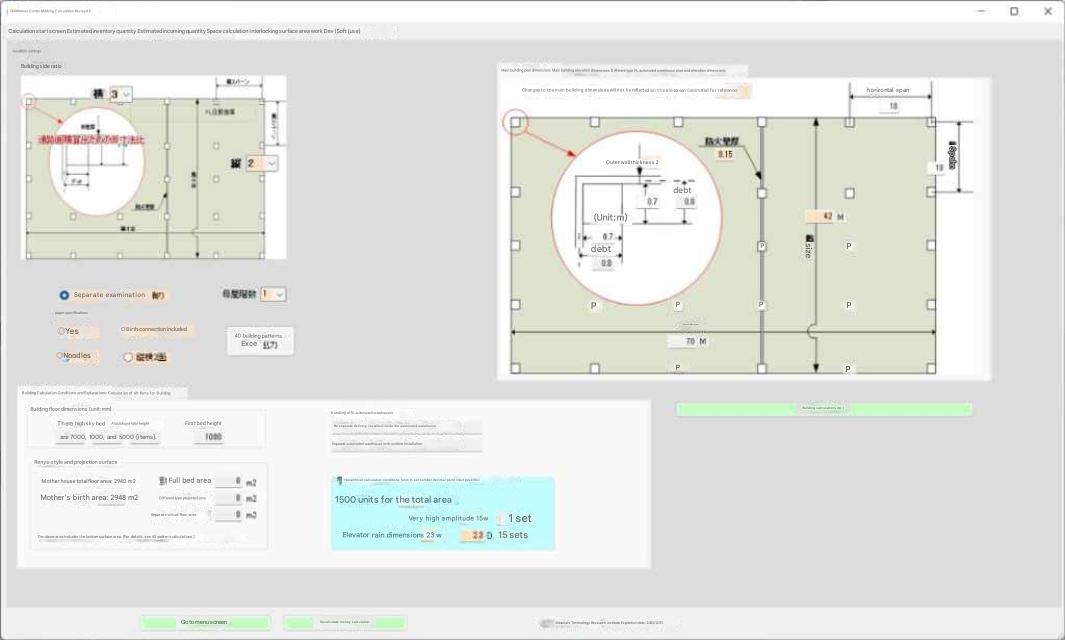

Item 1 Building aspect ratio

| Tera Calculation 2 does not have a concept of dimensions in space area calculation. Building

dimensions are calculated by specifying the building aspect ratio. Aspect

ratios of 1 : 1 or 2 :1 are rare, and rectangular distribution centers with aspect ratios of 3 :2 or 4:3 are common. |

|

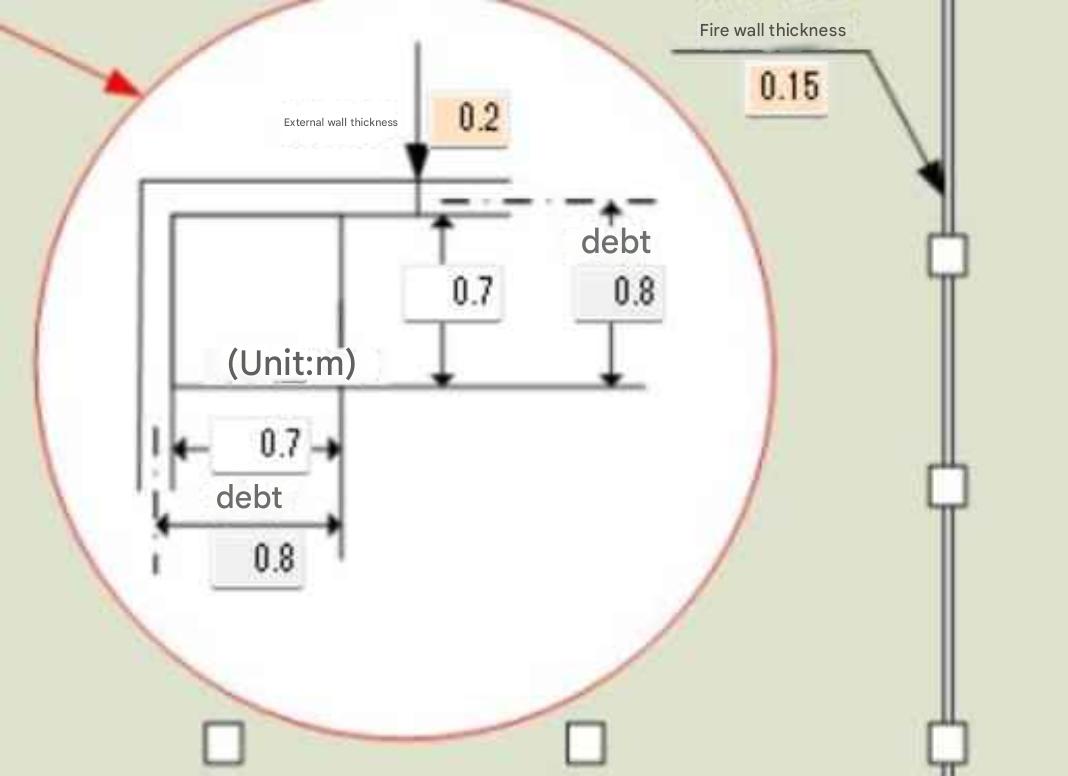

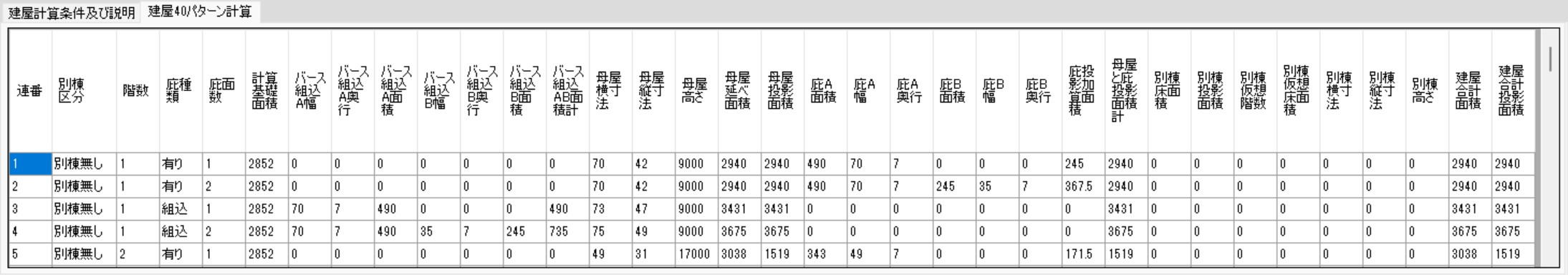

Section 2 External walls , pillars, and fire walls

|

|

While columns need to be strong enough (material, thickness, and length and width dimensions) to support the building, in a multi-story distribution center, the walls also play a role in maintaining the building's strength (called structural walls). Therefore, modifications such as creating openings in walls cannot be made after construction.

Tera settings are 200mm for exterior walls, 700mm x 700mm for columns per floor, with a 100mm increase for each additional floor , and a column pitch of 10m . The building's projected area is calculated based on the exterior

wall thickness center (100mm inward for a 200mm wall thickness). Changes

to Tera settings for exterior wall thickness, column span, and fire wall thickness are reflected in the area calculation. |

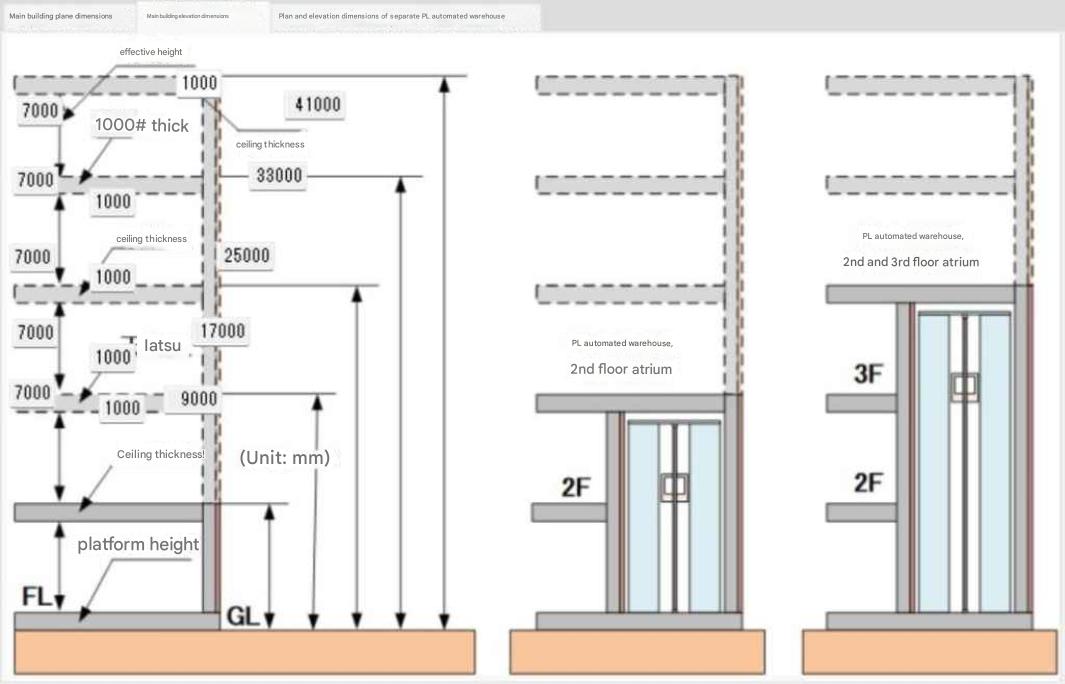

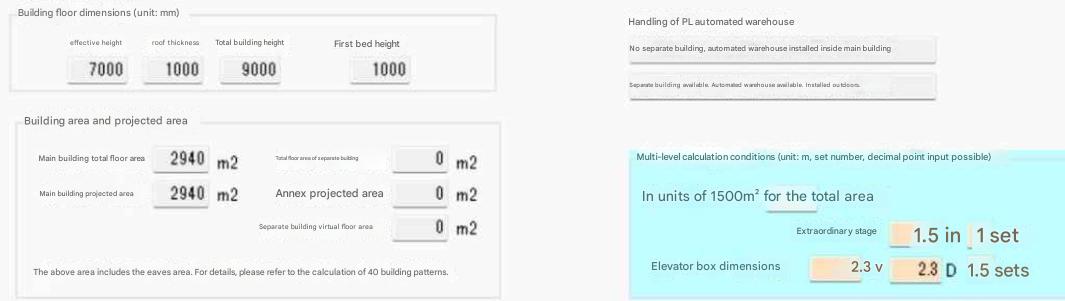

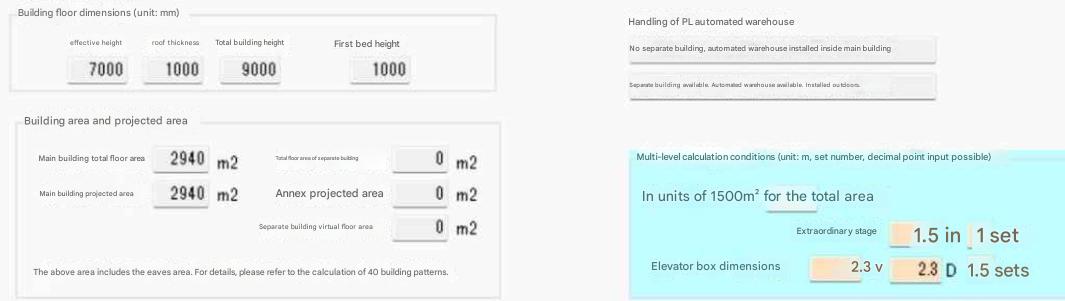

Section 3: Floor, beam and elevation dimensions

|

|

The first floor is a raised floor type with a height of 1000 mm , and the floor height is 7000 mm above the floor of each floor. The floor height is calculated assuming the floor thickness + beam height is 1000 mm . |

Section 4: Multi-storey and eaves

Eaves are rain protection roofs installed at the entrances and exits of distribution centers. Buildings with three or more floors do not have eaves, and trucks often enter the building (called a berth-integrated type in Tera calculations). 50% of the eaves area is added to the building's projected area, and the building coverage ratio is (building projected area + eaves area * 50% / ) / site area.

|

Section 5 Emergency stairs and elevators

For buildings with two or more floors, the area of emergency stairs and elevators is added.

Tera calculations assume that a fire wall is installed for every 1500 m2 of the total building area, and that a 1.5 m wide emergency staircase and ( 2.3 m2 * 2.3 m2 freight elevator area * 1.5 sets) are added for every 1500 m2. |

Item 6 Main building and separatePLautomated warehouse

|

|

Typically, a distribution center is completed in one building, rather than multiple buildings.

However, there are rare cases where an automated warehouse is constructed as a rack building (a building with no building columns, with walls and a roof attached to the shelves) and a separate building is built. Although it is rare, it affects the site layout (especially the width of the site's aisles), so we decided to incorporate it into Tera Calculation 2. Automated warehouses have many shelves to increase the return on investment, and with more shelves, the second and third floors become open-air structures. A building with no floor (open-air structure) is not good from both a structural and cost perspective. When introducing an automated warehouse, we believe it is worth considering whether to have the automated warehouse as a separate building or to incorporate it into the distribution center (main building).

|

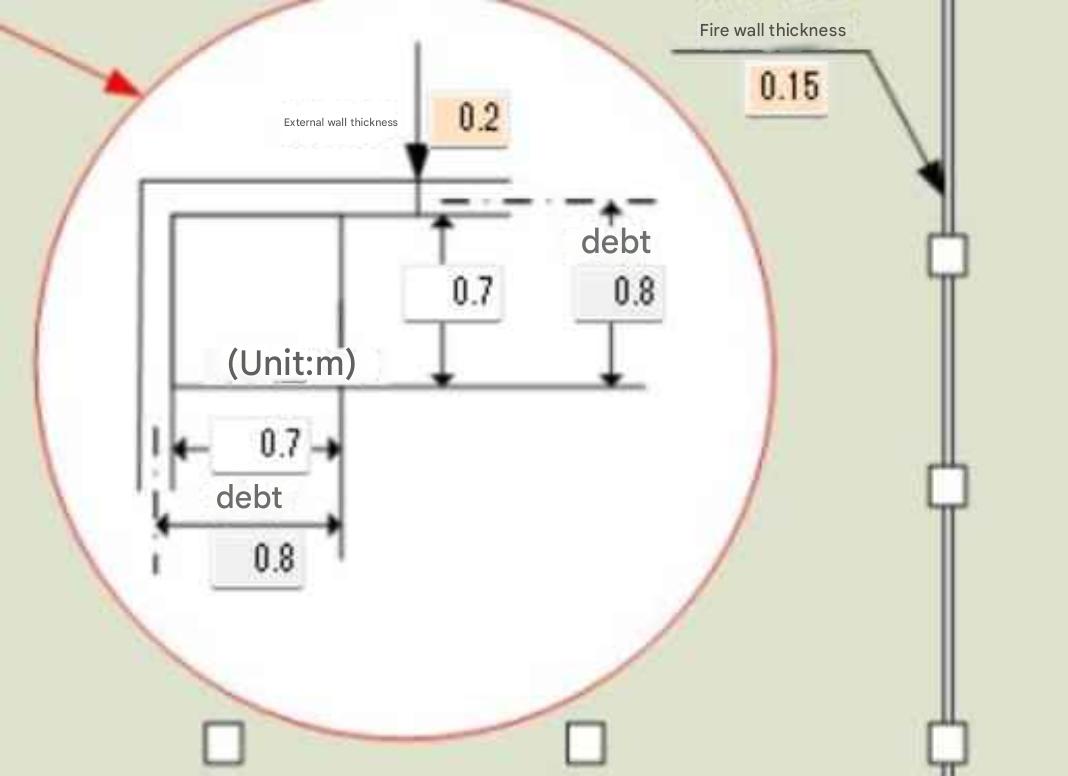

Section 7: Calculation of 40 building types

|

|

| There are 40 different building type patterns: 2 separate building categories (separate building A and separate building B have the same area) * 5 floors * 2 with or without eaves * 2 berth surfaces = 40 different patterns. The area and main dimensions of these 40 patterns have been calculated and compiled into a list ( which can be exported to Excel ). The site area screen obtains building information from this list. |

Section 8 Building specifications and calculation of multi-storey center

| You can change the settings on the building area screen, such as the number of floors and whether or not there is an outbuilding, to see how the length and width of the building (main building) changes, but this display is temporary and is not reflected in the site area calculation. (Building type 40 pattern calculation is used for site area calculation.) |

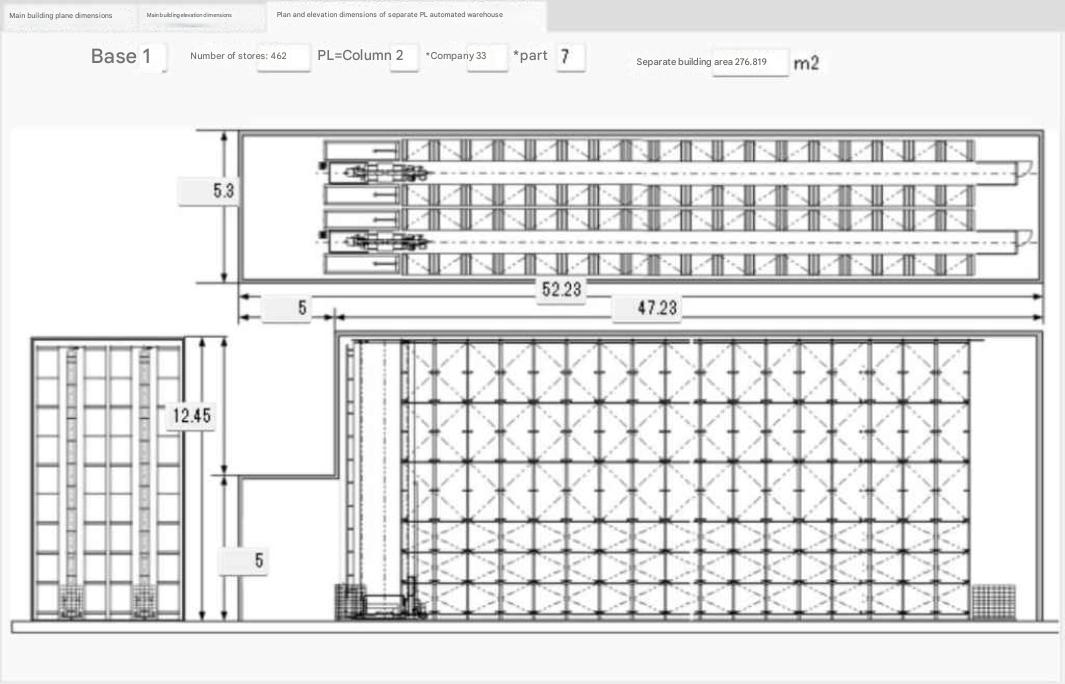

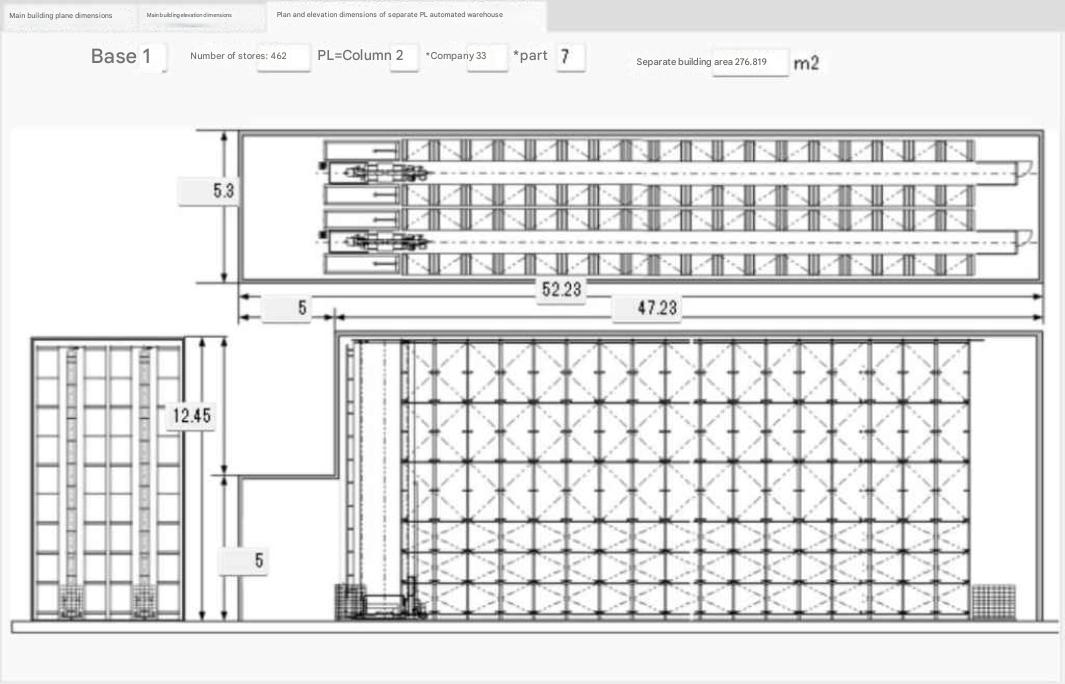

Item 9 Main building plan dimensions

| The dimensions of the building (main building) are displayed on the building area screen, and the vertical dimensions can be changed to check the horizontal dimensions, but this display is temporary and is not reflected in the site area calculation. |

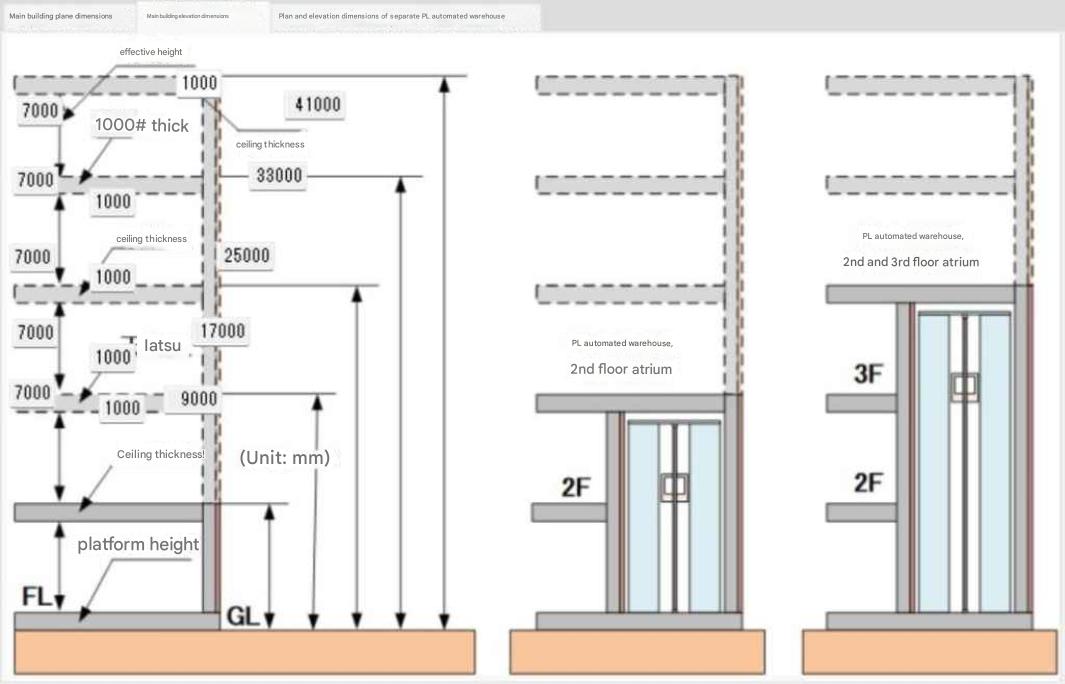

Item 10 Main building elevation dimensions

| Although it is not used for calculating the area, the height dimension is displayed to give an idea of the building. |

Item 11: Plan and elevation dimensionsof separatePLautomated warehouse

The diagram and approximate dimensions of the PL automated warehouse (rack building) when a separate building is used are provided.

|

|

|