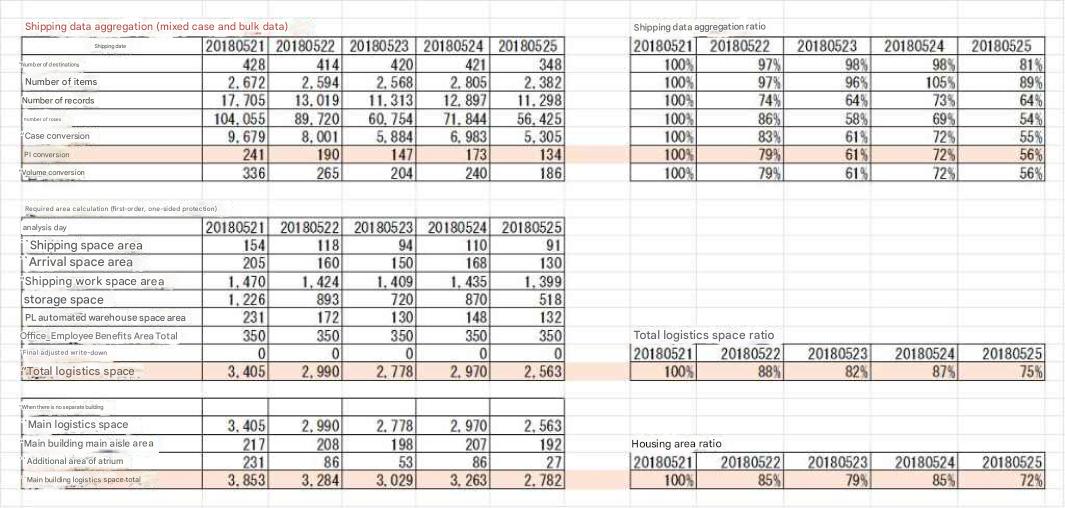

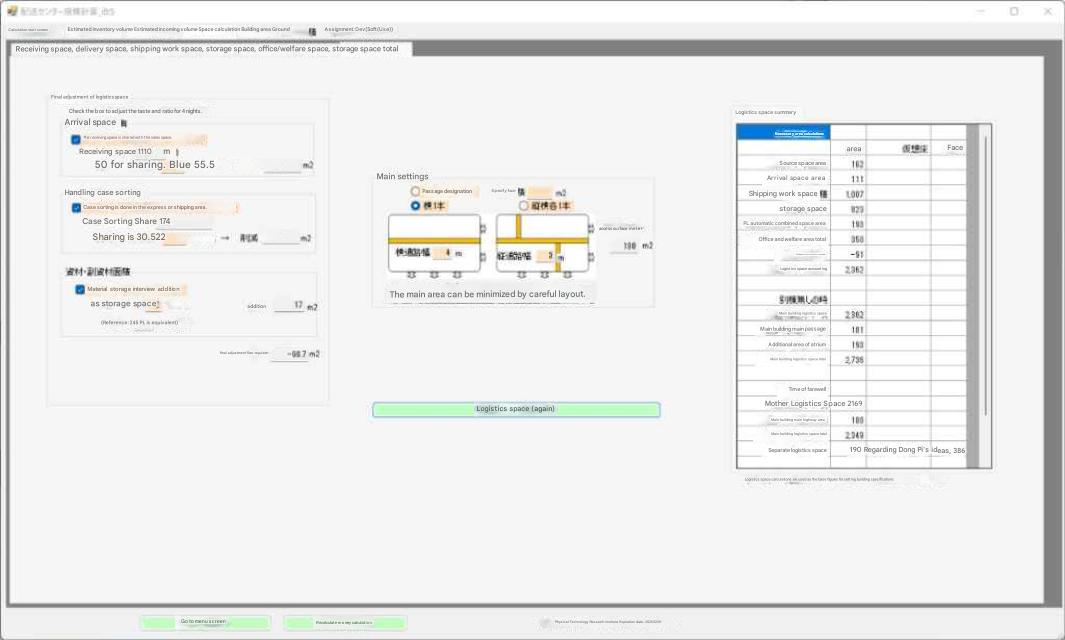

The logistics space area is calculated by separately calculating the shipping space area, receiving space area, shipping work space area, storage space, and office / welfare area . These areas can be shared during non-working hours or by devising work operations. Spaces that can be shared to reduce the logistics space area are receiving and case sorting. Also, spaces that must be added to the above calculations include the material and auxiliary material storage area and the main aisle.

Section 2. Sharing of Receiving Space

Normally, incoming goods are concentrated in the morning before shipping. If the incoming goods volume in the morning is 60 % and the shipping space can be used 100% as incoming goods space, the load on the incoming goods space will be reduced by 60 %. There are other calculation factors involved in the area calculation, so it is not possible to simply say there is a 60 % reduction, but it is certain that there will be a reduction. Space calculations are not incorporated into the Tera settings, but we would like you to consider this.

|

Item 3. Case Sorting Sharing

|

Case sorting is assumed to be a continuous operation with sorting out of the storage space. Case shipments involve a large volume of items, leaving the shipping space empty before sorting, some of the main aisles are infrequently used, there are infrequently used loading and unloading aisles in parts of the storage space, and work efficiency will not decrease even if the sorting spaces are dispersed as long as they are on the path from the storage space to the shipping space. There are elements that can be shared between the sorting space and other spaces.

Tera settings do not incorporate space calculations, but this should be considered.

Item 4: Area of materials and auxiliary materials

|

This includes shipping cardboard boxes, packaging tapes, unused shipping labels, and various forms.

Because the storage ratio of shipping cardboard boxes is high, the amount of cardboard shipped (used for bulk shipping) is the determining factor for the area. In Tera settings, if 1,000 PL of products are stored in the storage space, the area is set to 20 PL (storage space PL number * 2%).

Section 5: Main Passage Configuration

If the receiving space and storage space are not adjacent, or if the storage space and shipping space are not adjacent, a conveyance aisle is required.

Tera settings calculate the horizontal dimension of the distribution center as 4m, but as a guideline, consider 50 % of the above calculation .

Item 5. Logistics Space Count

|

The final adjustments to the logistics space and the total logistics space taking into account the main passageway will be used as the basic figures for setting the building specifications.

|