Section 3: Calculation of inventory (storage quantity) |

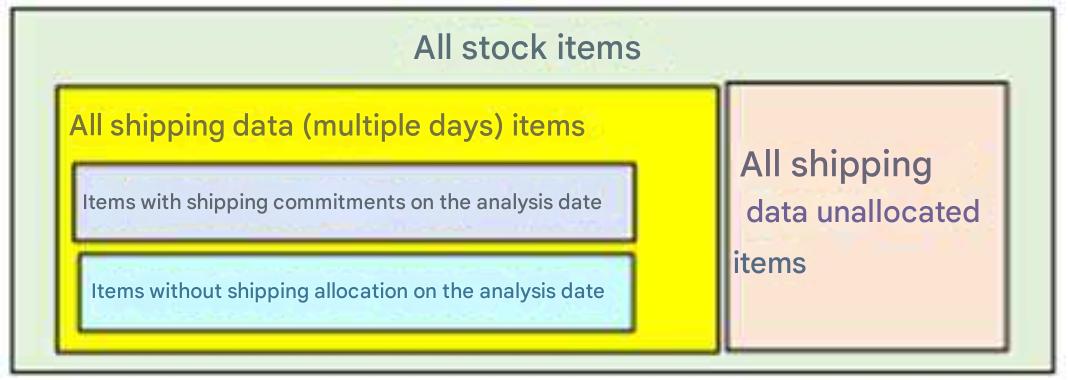

Inventory can be expressed as " cumulative arrivals - cumulative shipments = inventory ." Because shipments are orders from customers, the distribution center cannot increase or decrease shipping quantities or change delivery dates based on its own convenience. It is necessary to maintain inventory to prevent stockouts despite the daily fluctuations in shipping quantities. At the same time, to reduce inventory costs and due to distribution center size constraints, it is desirable to keep inventory levels as low as possible. Inventory is managed for each item using the following calculation: average shipment volume * number of days = maximum inventory. Receiving involves placing an order with a supplier and having the product delivered to the distribution center to ensure sufficient inventory. While shipping dates and shipment volumes cannot be changed, the distribution center can specify the quantity and delivery date and time for receiving. Based on the above assumptions, Tera calculates inventory and arrival volumes from shipping data . |

|

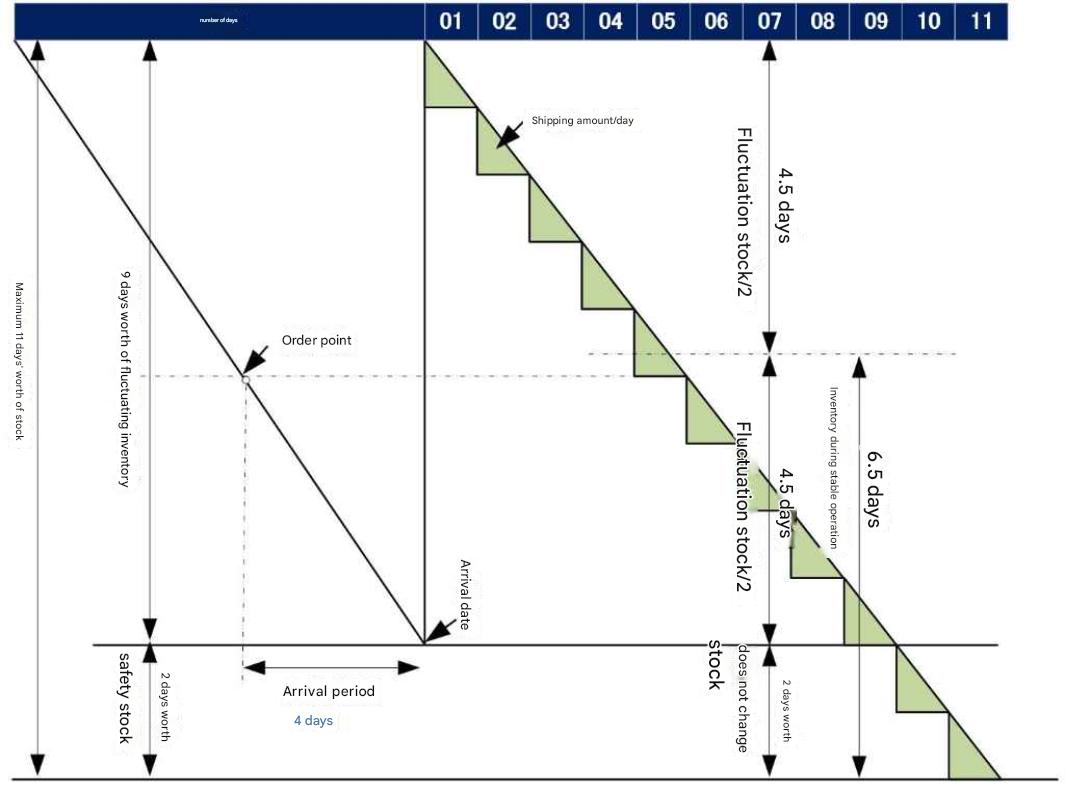

Shipping volume/day uses the average value of all data. Tera calculates inventory storage volume using the following method: Inventory volume (storage volume) during stable operation = Safety stock + (Fluctuous stock/2) Fluctuous stock = Maximum inventory - Safety stock. For example, suppose there are 18 items with a maximum inventory period of 11 days, safety stock period of 2 days, and fluctuating inventory period of 9 days . If three of these 18 items are received every day , the fluctuating inventory storage volume = (Fluctuous inventory/2). If calculating inventory volume (storage volume) during steady operation seems impossible in practice, you can simply add a margin rate after the above calculation. |

Note: The reorder point is not relevant to inventory calculations. The reorder point is the amount of inventory ordered at a time that guarantees the amount of inventory for the period from ordering to receiving the goods.