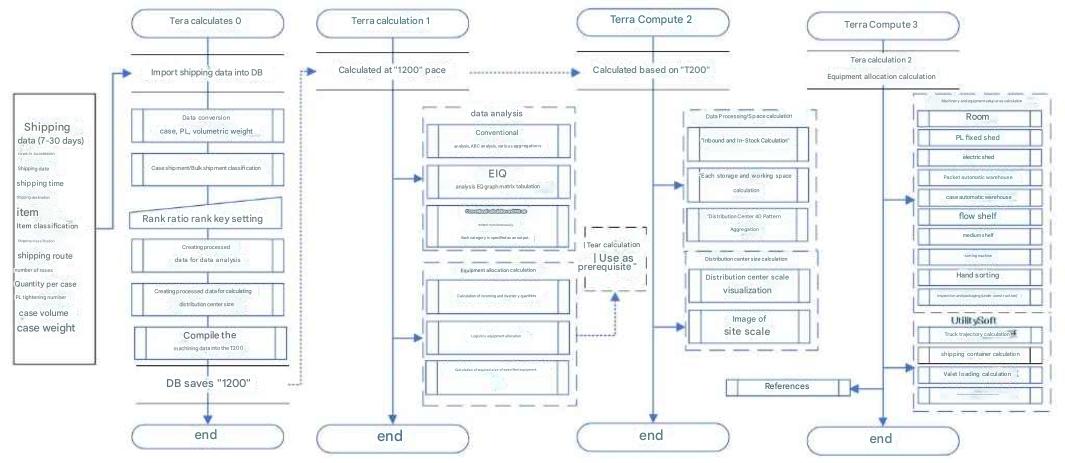

Item 1 Software Flow Diagram

|

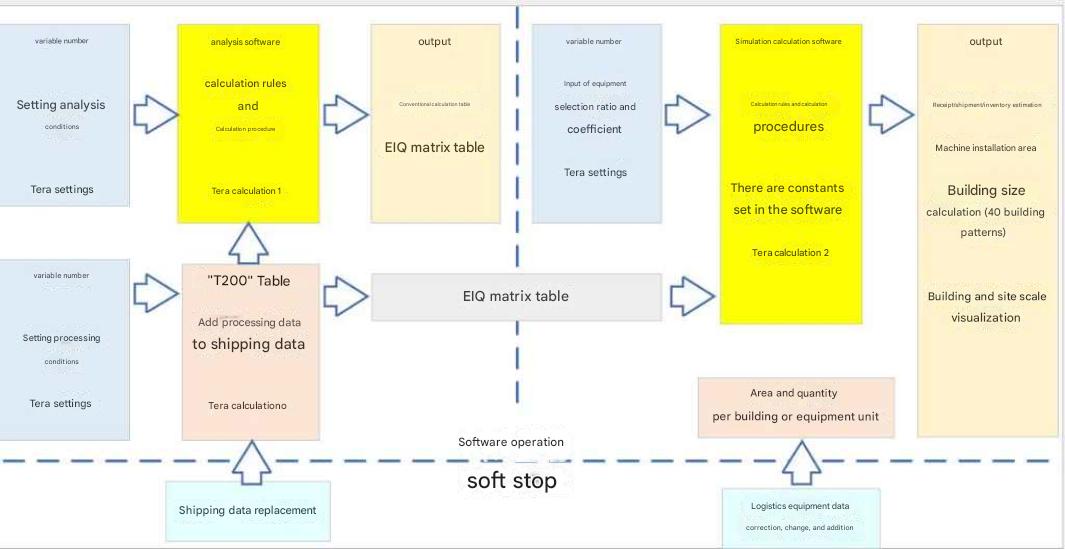

| Tera Calculation Software Tera Calculation 0 - Shipping Data Processing Frequently used calculations in Tera Calculation 1 and Tera Calculation 2 are pre-calculated and stored in Access (the "T200" table). Tera Calculation 1 and Tera Calculation 2 are based on "T200." Tera Calculation 1 - Shipping Data Analysis Calculation/Equipment Allocation Using EIQ analysis, data is divided into 25 categories by shipping rank and output to an EIQ matrix table. In addition, equipment is allocated to the EIQ matrix table and the required size of that equipment is calculated. Tera Calculation 2 calculates incoming and outgoing shipments and inventory, calculates the required floor space for each piece of equipment according to Tera settings, and automatically calculates distribution center size and site area. You can change one or more Tera settings and recalculate with all changes reflected. Calculates 40 different building sizes, including the number of building floors and berths. This allows you to visualize the tradeoff between building size and site size. Tera Calculation 3 is a utility software that calculates the floor space of each piece of equipment. After calculating the required size of equipment using Tera Calculation 1, the software user calculates the floor space for each piece of equipment and sets the size of the distribution center. By imitating the procedures and methods used in Tera Calculation 2, users can learn how to set the size of a distribution center using Tera Calculation 3. Reference materials are also included. Tera Calculations commonly distinguish between case-based and bulk shipments. Selective aggregations are available for the number of shipments, number of bulk shipments, case conversion, product liability conversion, volume conversion, and weight conversion. These aggregations can also be conditionally aggregated by specifying "shipping time," "shipping route," "item classification," and "shipping classification." In addition, calculations are performed simultaneously using the calculation method and the EIQ method, allowing users to check the differences. |